Your highlights at the trade fair

- Discover our wide range of cosmetic products, from liquid to solid. Thanks to our broad portfolio and additional specialized technologies such as aerosol filling and powder processing, we cover all areas of skin care and cleansing cosmetics. As a contract manufacturer and contract filler for cosmetic products, we are the partner of choice for natural cosmetics, specialty cosmetics, clean beauty and phyto cosmetics, as well as luxury cosmetics and medical applications.

- Aerosols as boosters for sun protection: Aerosols offer enormous potential for taking sun protection products to a whole new level! Although spray can technology is already well known, it is full of untapped possibilities: less oil, no crystallization, yet maximum stability and performance—propellants as solvents make it possible. Our trade fair team will be happy to show you the options on site.

- Aerosols for chemical-technical products: In various areas of application, we prefer bag-on-valve technology for contract filling of chemical products. Compared to conventional aerosol technologies, bag-on-valve offers longer shelf life, optimal spraying capabilities, complete emptying of the can, and hygienic purity thanks to separate compartments for propellant gas and air as an environmentally friendly propellant.

- New face in the sales team: Meet our newest team member, Alexander Güttner, in person.

- Trade fair team on site: André Keller (CEO), Ronnie Heusser (Sales Manager BU Care), Alexander Güttner (Project Manager Sales), Marc Devaux (Project Manager Sales), Danja Keller (Operations Manager Frike Cosmetic AG), Nikolai Czech (Aerosol Developer)

Let's talk about your ideas

Benefit from our many years of expertise as a Swiss contract manufacturer and discuss your current projects and ideas with our trade fair team. Visit us at booth S64.

February 5, 2026: 9:00 a.m. – 7:30 p.m.

February 6, 2026: 9:00 a.m. – 5:00 p.m.

Sounds exciting? We look forward to welcoming you soon in Paris.

«Would you like to arrange an appointment with us at the trade fair in advance? I am at your disposal.»

Aerosols are more stable, more pleasant, and more sustainable.

Many modern UV filters are poorly soluble. In classic pumpable formulations, this leads to instability — for example, through recrystallization — and a greasy skin feel.

The use of propellants such as dimethyl ether (DME) significantly improves the solubility of UV filters. At the same time, these dry propellants replace oily components, resulting in a lighter, faster-absorbing skin feel—without any loss of UV protection performance.

Development of sun protection products

Aerosols enable stable, highly effective, and sensorially appealing sun protection products — in line with current market trends. For over 20 years, the FRIKE GROUP has developed countless sun protection lines for national and international customers. From premium to mass market, we offer various formulations and forms: from sprays to creams to oils. On request, we develop sun protection products with mineral filters such as zinc or titanium, which protect our skin from optical radiation by reflecting, scattering, and absorbing it. Alternatively, we also offer sun protection products with organic filters to filter out the ultraviolet portion of light and thus prevent sunburn.

«Sounds exciting? Let's talk about your ideas and upcoming projects!»

Discover our product range

Thanks to a broad portfolio and additional specialized technologies such as aerosol filling and powder processing, we cover all areas of skin care and cleansing cosmetics.

Your highlights at the trade fair

- Discover our wide range of pharmaceutical products, from liquid to semi-solid. Our trade fair team will show you our extensive manufacturing and filling options, as well as specialized technologies such as emulsion processing.

- New face in development: Meet our new Head of Pharmaceutical Development, Niklas Stroh, in person.

- New trade fair design: In keeping with the new website, our stand has also been given a makeover and now shines in new splendor.

Let's talk about your ideas

Benefit from our many years of expertise as a Swiss contract manufacturer and discuss your current projects and ideas with our trade fair team. Visit us in Hall 6 at Stand 0B15 – from 10:00 a.m. to 6:30 p.m. each day.

October 28: 10:00 a.m. – 6:30 p.m.

October 29: 10:00 a.m. – 6:30 p.m.

October 30: 10:00 a.m. – 4:00 p.m.

Sounds exciting? We look forward to welcoming you soon in Frankfurt.

Your Swiss pharmaceutical contract manufacturer

With 40 years of expertise as a pharmaceutical contract manufacturer, the FRIKE GROUP is one of Europe’s leading specialists in this area. We use process mixers from 2.5 to 3000 liters to manufacture non-sterile, semi-solid and liquid formulations and suppositories. Thanks to our wide range of mixers, we are well set up to develop new formulations, including scale-up to the batch size you require. We also have impressive, wide-ranging solutions and expertise when it comes to packaging and filling.

Whether you are planning a production campaign, large or small, want to have new formulations developed or optimize your existing ones, we are your expert partner. In every collaboration, efficiency, innovation, confidentiality and customer friendliness are our top priorities.

«Would you like to schedule an appointment with us at CPHI in advance? I am happy to assist you.»

Welcome to booths C484 & C485 in Convention Hall

66 countries, 326 exhibitors, and 164 specialist presentations—the Sepawa Congress has been an important networking event in the chemical engineering industry for many years. Meet our trade fair team and discover our diverse range of services as Switzerland's largest independent contract manufacturer. We develop and produce everything from pharmaceuticals and cosmetics to chemicals. Discuss your current projects and ideas with our trade fair team. Expand your knowledge of aerosols and attend the exciting specialist presentation by our aerosol expert Nikolai Czech on October 17 from 10:00 a.m. to 10:30 a.m.

Sound exciting? Get your copy now.

We are happy to provide you with some useful links to the congress and last year's presentation as a download. The latest presentation by speaker Nikolai Czech, “Aerosols as SPF boosters – how does it work?”, will be available here on October 17, 2025, at 5 p.m.

What we particularly noticed:

Sustainability Remains the Focus

Recyclable packaging, refill solutions, and environmentally friendly materials were the focus of many exhibitors. The trend toward "green beauty" has long been more than just a marketing promise – it is having a lasting impact on product development and brand positioning this year.

Clean & Conscious Beauty

Supply chain transparency, short INCI lists, and functional, minimalist formulations remain on trend. Consumers want cosmetics that are both effective and responsible.

Smart Packaging & Digitization

Packaging is becoming increasingly interactive: QR codes for traceability, digital product information, and NFC technology are creating new opportunities for customer proximity and trust.

Networking and Exchange

The trade fair once again provided our team with an ideal platform for personal discussions, new contacts, and concrete project ideas. Many thanks to everyone who stopped by!

FRIKE was once again the lanyard sponsor of the fair!

We're proud to be a visible part of the industry – and were supported by literally every trade fair visitor.

We're already looking forward to CB 2026!

Tosca Winkler, Head of Marketing

Ronnie Heusser, Sales Manager FRIKE Cosmetic

What has changed?

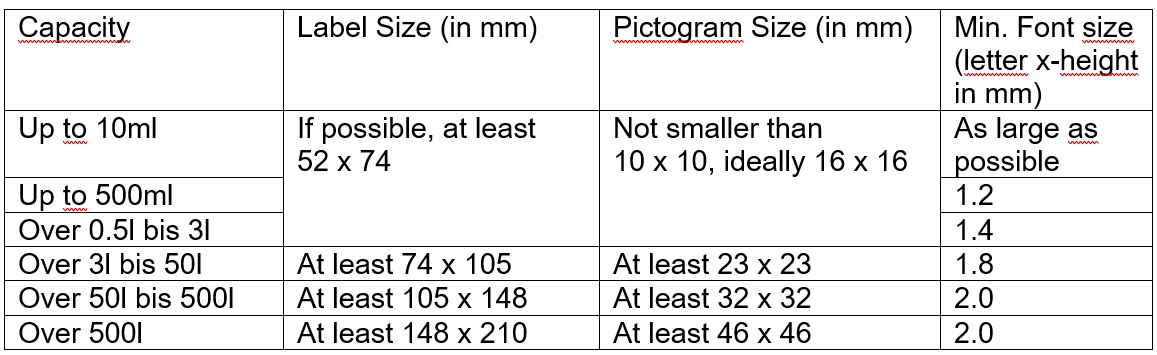

Revised labeling requirements

- Sans serif, black font on a white background

- Font size depends on the packaging volume (see table below)

- Line spacing is 120% of the font size

- Folded labels are now generally permitted – all formatting requirements also apply to them

Our regulatory team takes these new labeling requirements into account when creating their layouts.

New requirements in advertising:

- For dangerous mixtures, pictograms, signal words and hazard statements (H and EUH phrases) must be included in advertising.

For advertising campaigns aimed at the general public, the following additional notice must be included:

"The information on the product label must always be followed."

New hazard classes according to Regulation (EU) 2023/707 of 19 December 2022

The following new hazard classes have been introduced, each with specific EUH phrases:

- Endocrine disruptors (EUH380, EUH381)

- Environmentally harmful endocrine disruptors (EUH430, EUH431)

- Persistent, bioaccumulative, and toxic (PBT/vPvB) (EUH440, EUH441)

- Persistent, mobile, and toxic (PMT/vPvM) (EUH450, EUH451)

Transitional periods

Switzerland

- For Switzerland, the final implementation is still being clarified and is expected with the packages of measures next autumn.

EU

- In the EU, the deadlines are regulated as follows:

Fabrics:

- New substances must be classified and placed on the market according to the revised CLP Regulation starting May 1, 2025. For substances placed on the market before May 1, 2025, a transition period applies until November 1, 2026.

Mixtures:

- New mixtures must be classified and placed on the market according to the new CLP Regulation starting May 2026. A transition period until May 1, 2028, applies to mixtures already placed on the market before this date.

Marcel Fankhauser, Regulatory Affairs

From August 22nd to 24th, 2025, Ebnat-Kappel will be a meeting place for young and old. As part of the popular street festival—this year combined with the municipality's 60th anniversary—FRIKE Cosmetic AG will open its doors to the public on Saturday, August 23rd.

📍 Open Day – Saturday, August 23, 2025

🕘 09:00 bis 16:00

📌 Ort: FRIKE Cosmetic AG, Ebnat-Kappel

Experience exciting insights into the world of cosmetics production – from the initial idea to the finished cream. With factory tours, information points, employee encounters, and little surprises, there's something for everyone.

We look forward to your visit!

Find out more about the street festival here.

Michael Jufer, Director BU Care

Not all water is the same. The application makes the difference.

The production conditions at the customers, mainly producers in the paper, pulp and cardboard industry, determine how the process water is used and reused. There are always different requirements for the circulation treatment of process water depending on the location and product. Servophil AG has a high level of expertise and experience with a variety of technologies that can be used to meet a wide range of requirements.

Applications range from fresh water, cooling water, PM screen water and pulp circuits to recycled waste water. Water scarcity has become a growing problem for manufacturing industries in Europe. Servophil services include

- Preservation and disinfection

- Deposit prevention

- Remote monitoring of dosing systems

- Consulting and on-site production-related problem solving.

Servophil AG is mainly active in Switzerland, Germany, Austria, the Netherlands, Belgium, Slovenia, Scandinavia, Finland and Poland. The experts are represented in all these regions and are available to customers on site to solve challenges quickly, individually and efficiently.

About Servophil

Servophil AG positions itself as an innovative provider of process water treatment using specialty chemicals, dosing systems and on-site service & consulting in the paper and manufacturing industries. Our goal is to create a strong market position, long-term growth and sustainable customer relationships through high-quality products, control and service. Our vision is to be the preferred choice for customers in the DACH region and near Europe (Benelux/PL/CZ/SVK/SLO/IT) through innovative technologies and first-class service.

The Paris Packaging Week is opening its doors again, and as always, we are excited to be part of it with our own stand.

Visit us on January 28th and 29th, 2025, at Stand S62. Our Sales Team is looking forward to making new connections and discussing exciting future projects with you.

We can’t wait to see you there.

Your FRIKE Cosmetic Team

🎄🎄The Grand FRIKE Christmas Celebration on Uetliberg near Zurich🎉🎉🎉

In honor of our 80th anniversary, we celebrated together with all 6 of our companies for the very first time – and it was an unforgettable evening! 🌟

At the elegant Uto Kulm hotel, with a stunning view over Zurich, we kicked off the evening with a cozy campfire aperitif. 🔥🍹

Following this, around 250 employees enjoyed a festive dinner 🍽️ and danced the night away to captivating music by a DJ and a saxophonist. 🎷🎧 The atmosphere was simply fantastic – with plenty of dancing and fun all around! 🕺💃 The only challenge? Trying to capture everyone in a single group photo – with just a smartphone. 😊

A big thank you to everyone who made this evening so special! 🙏 We’re already looking forward to the next 80 years – together with all of you.🥂✨